Infrastructure & Facility

We have a sound infrastructural base that assists us in developing highly functional pipes and tubes. Our well furnished in house drawing facility along with endless number of dies, cutting & straightening facilities enable us to develop any odd size in variant thickness whether in round, square, rectangular or capsule sizes.

To keep pace with the advancement in the technology, we continually upgrade the production machines. Tubes manufactured are further taken to different processes like annealing (Roller Hearth Annealing Furnances with controlled atmosphere), drawing on modern draw benches etc forthe manufacture of a wide range of ERW & CDW precision tubes with close tolerance.

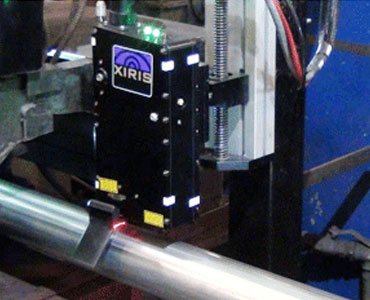

A special procedure is developed to process smooth ID with mirror view finish and close tolerance for CBQ/SSID Tubes, these tubes are used for hydraulic cylinders, Shock absorbers, front fork and gas spring. Further, all tubes are put through online Eddy Current Tester and are also physically checked for quality before they are packd and dispatched.

Our Team

We boast of a qualified team that is well versed with the production of pipes and tubes. Owing to vast experience of the team, we have been offering high quality pipes and tubes. All their industrious efforts lead to provide utmost level of satisfaction to the valuable clients.