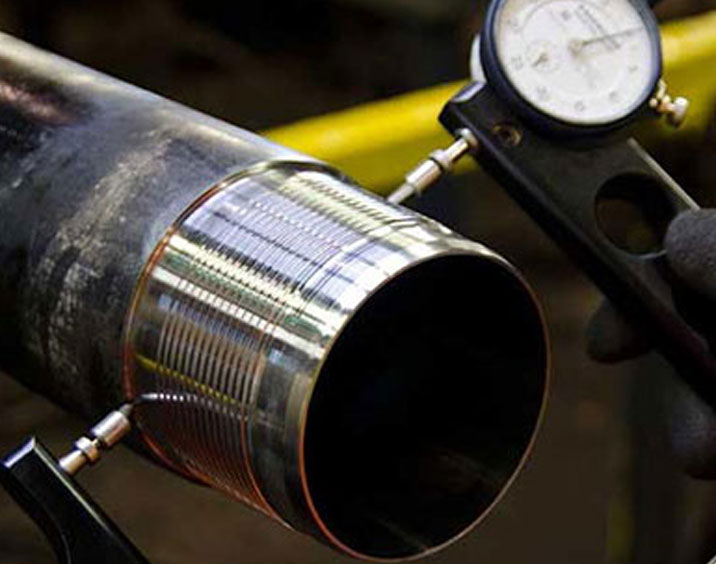

Quality Assurance

Quality is the prime concern of the organization. To assure the quality, we conduct stringent quality tests at every level of production starting from the procurement of raw materials to the finished product.

Our experienced quality control executives keep a strict vigil on the production process that ensures the development of the impeccable pipes and tubes. Our endeavour is to create a working environment where motivated employees communicate freely and where innovation is encouraged, to enable continual improvement in all areas.

All our employees work together to achieve “Complete Customer Satisfaction through Total Quality Management”. Our complete focus is towards consistent quality, adhere to delivery schedule, customized product mix, competitiveness and immediate compliance of complaints, a policy which has become a habit now.

- State-of-the-art technology in quality control program.

- Appropriate statistical and modern testing facilities.

- Each products undergo stringent quality analysis.

- Test for welding Integrity, Eddy Current Test, Pressure Test.

- laboratories equipped with electronic microscope, micro hardness tester to name a few.

- Magnetic Crack Detection and Die Penetration Inspection.

- Tensile Inspection, Hardness Inspection, Dimensional and visual inspection for thickness.

- Final product dispatch after certification.